Textile industry plants operation

Industrial fumes purification and heat recovery systems

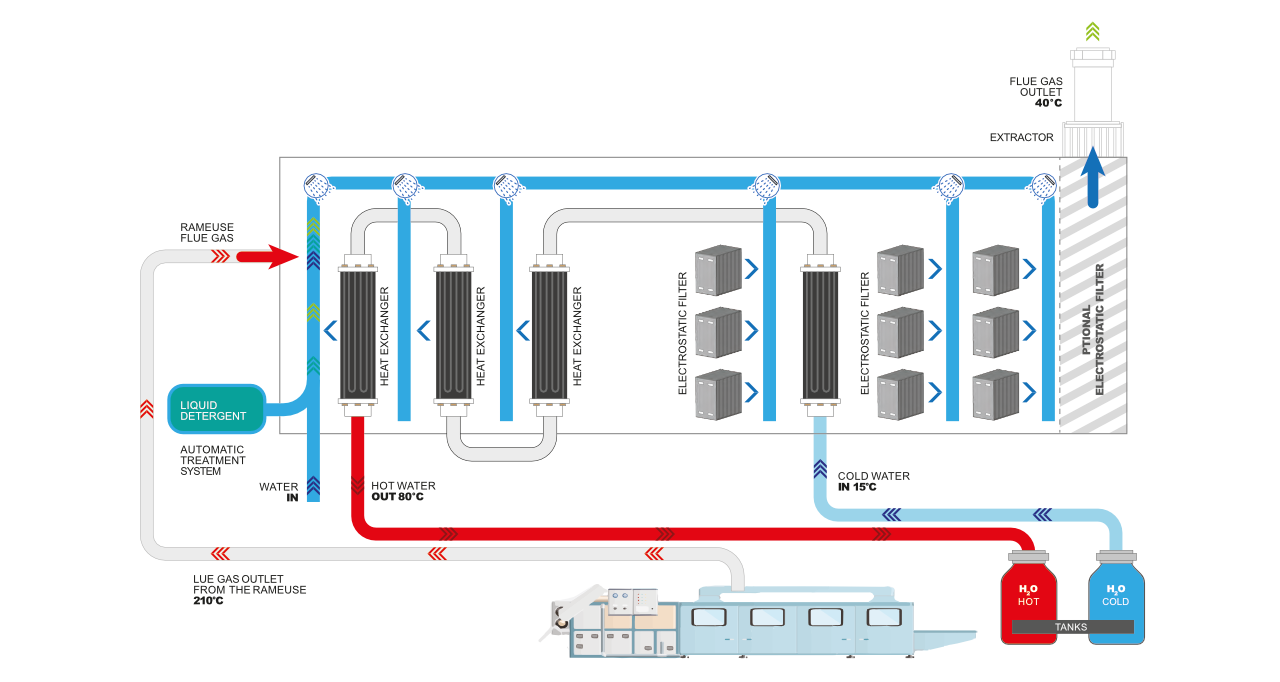

Standard plant with automatic treatment and the production of hot water

The new HRS plants remove oil mist from the flue gas with extremely high efficiency. The electrical field of the electrofilters is able to capture all the droplets of the oil mist. In the first part of the HRS plant, the hot flue gas of the rameuses is cooled under controlled conditions to create the droplets, that is, the “oil mist”. The new HRS uses a High Efficiency indirect cooling system managed with

an open circuit controlled by a modulating valve to guarantee correct cooling. This system enables recovery of all the heat present in the flue gas, transferring the same Kcal present in the flue gas to the water. In this way the Client is guaranteed good quality hot water to use in the various processes. This is the solution that best exploits the heat recovery process.

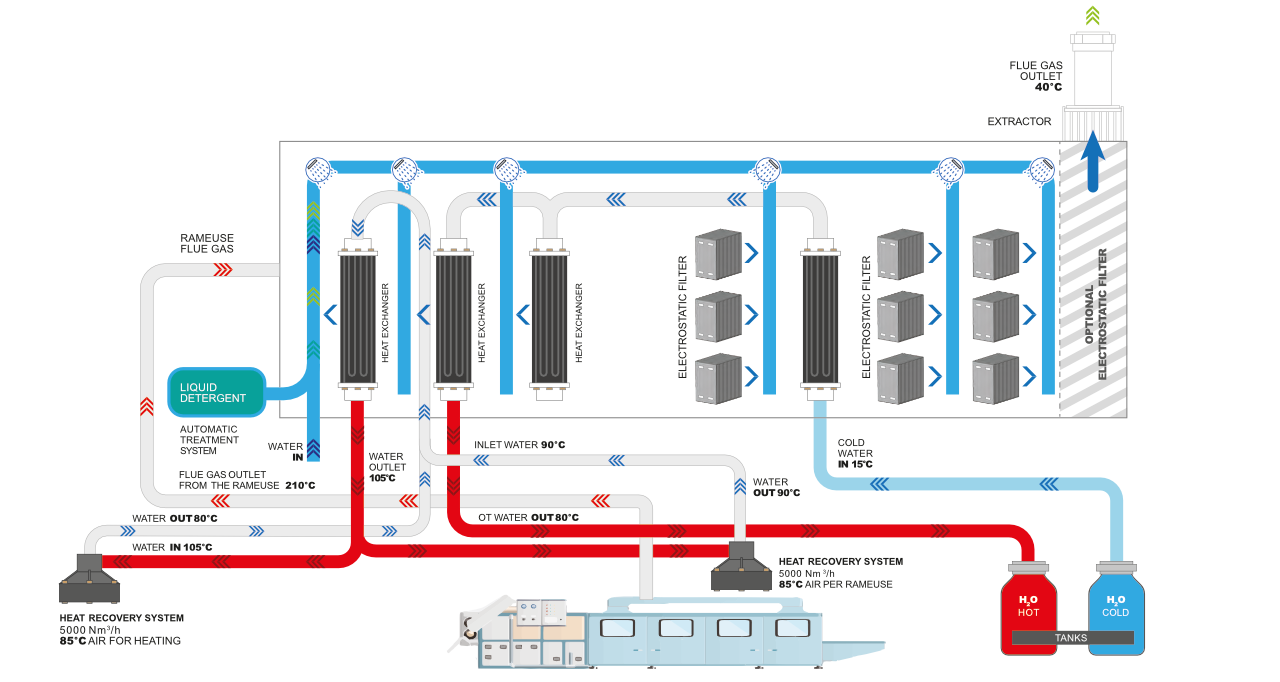

Mixed plant with automatic treatment and heat recovery

For Clients that need to treat the rameuse flue gas that heat set, but do not require large quantities of hot water, we can install a “mixed” plant. In this solution, a “closed circuit” is installed on the first standard heat exchanger of the new HRS. This exchanger will be connected to two heat recovery systems for the generation of hot air. The air of the first heat recovery system can be sent

back into the rameuses, thus reducing the consumption of gas. The air of the second heat recovery system can be used to heat the shed or conveyed outside during the summer months. The cooling of the flue gas continues with an open circuit like in the standard HRS plants, in any case allowing a good production of hot water.

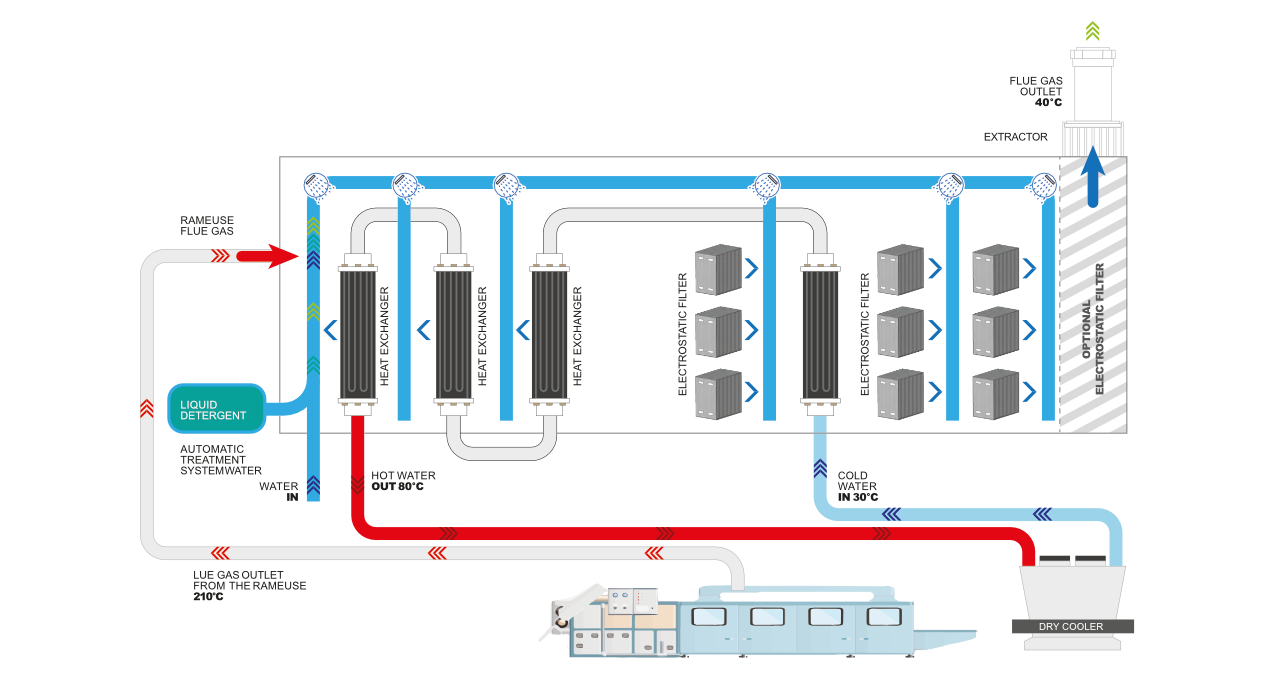

Standard plant with automatic treatment but no heat recovery

For Clients that need to treat rameuse flue gas that heat set, but do not require hot water, we can install an automatic plant without heat recovery. In this solution, a “closed circuit” is installed on all four of the standard heat exchangers of the new HRS.

The exchangers will be connected to a Dry Cooler to cool the same water. This solution is more “costly” than the first two but allows flue gas to be treated with completely automatic adjustments and without creating problems for the Client.